In the global printing market, anyone can buy a generic printer and slap a sticker on it. But in my experience, "generic" is the fastest way to become invisible. If you are looking to scale a brand, you don't just need a supplier; you need an engineering partner who understands that the hardware is the face of your company.

This is exactly why we've structured ZYWELL's OEM and ODM services differently. We've seen too many businesses struggle with "off-the-shelf" limitations—whether it's a label thermal printer that doesn't fit a specific medical casing or a portable printer that lacks the specific firmware encryption a government contract requires.

Real Customization vs. Surface Changes

Most factories treat "OEM" as a logo-printing service. At ZYWELL, we view it as an architectural challenge. When a client asks for a ticket thermal printer with a specific footprint for a kiosk, our "human-led" design process kicks in. We don't just ask about dimensions; we ask about the end-user's environment. Is it a humid kitchen? A dusty warehouse? A high-end boutique?

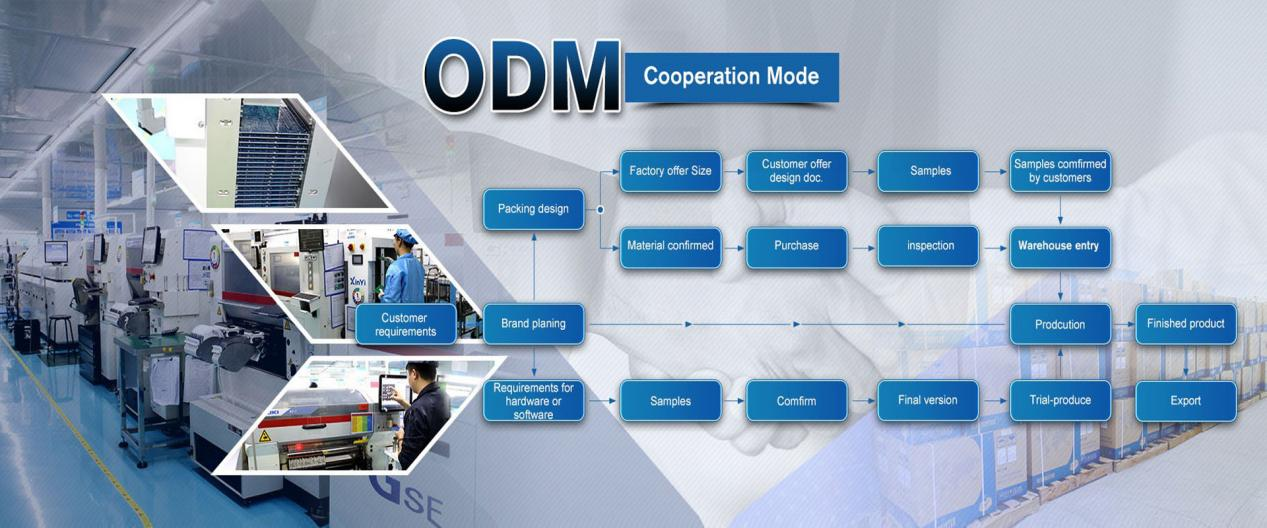

Our ODM capabilities allow us to build from the ground up. If your project requires a unique communication protocol or a specific ruggedized exterior for a portable printer, we don't say "it's not in the catalog." We sit down with the blueprints.

The biggest fear in manufacturing is the "copy-paste" culture. At ZYWELL, our partnership model is built on transparency. We understand that your unique hardware requirement is your competitive edge. Whether it's a proprietary housing for a label thermal printer or a specialized driver, we treat your IP with the respect a long-term partnership deserves.The goal isn't just to ship a container of printers. It's to ensure that when your customer unboxes that device, the quality reflects your brand's promise, not just our factory's output.